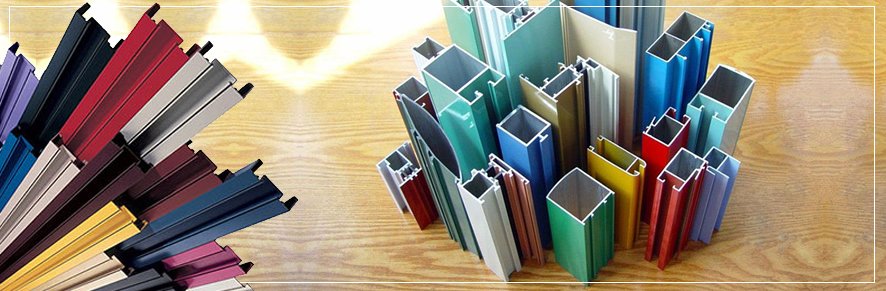

Our Firm Specialize in providing accurate composition of highly durable premium architectural powder coating, designed to provide exceptional longevity for any environment, without compromising powder coatings’ inherent sustainability characteristics. You can refer to a color card or paint swatches to ensure color accuracy.

AmeriCoats, a global Powder Coating manufacturer, was founded in 1998 by a group of experienced powder coating professionals. Drawing on our experience with several multi-national powder coating corporations and bringing a collective vision of the “best of the best”, AmeriCoats is now a multi-million dollar operation. Our core business, in fact our only business, is Powder Coatings. Dedicated to exceeding our customers’ expectations in service and quality, we use the best raw materials and quality control processes available. Continuous Improvement in service, manufacturing and quality is expected and rewarded among all our personnel. All manufacturing facilities are ISO registered and meet or exceed those standards. To view our global locations, please go to www.latinamericoats.com or www.royalpowdercoating.com

For interior use with some indirect UV exposure or where much better color stability in varying cure cycles is desired. Achieving a good balance between Epoxy and Polyester, these coatings are ideal on display/store shelving and most indoor appliances.

For interior and non-critical weathering applications where chemical, electrical, or possible livestock ingestion environments are encountered.

Typical applications are on lab furniture, water/well pumps, certain engine components, children’s' toys, certain electrical components.

This is the most "forgiving" exterior powder coating vs non-TGIC polyesters. Excellent weatherability, toughness and color stability are hallmarks. Appearance is best at 1.5 mils and over. Very flexible, these coatings can be "post formed" provided proper tooling setups are used. A wide range of cure temperatures and dwell times can be used.

Also referred to as Enhanced Polyester, our Super Durable product line, listed under the AmeriShield® registered trademark, is available for both exterior aluminum and fiberglass Architectural Trim and Components. These powders meet or exceed the performance requirements as defined by the AAMA 2604 and 624 specifications, exhibiting superior hardness and "stucco resistance" when compared to Kynar resin based liquids and powders. We offer a Five Year Limited Warranty to applicators with approved, qualified processes. Please ask your representative for details.

This coating uses a "Primid" type curing agent, developed as an alternative to TGIC curing systems. These coatings are used on a decreasing basis, primarily due to appearance issues at heavy film thicknesses.

Provides excellent leveling, smoothness and gloss. Superior hardness can be achieved (usually one "pencil" more than TGIC) and is designed for relatively low film build. Certain chemical resistances can be developed to a high level. This product is sensitive to cure parameters; they must be closely followed for optimum results.

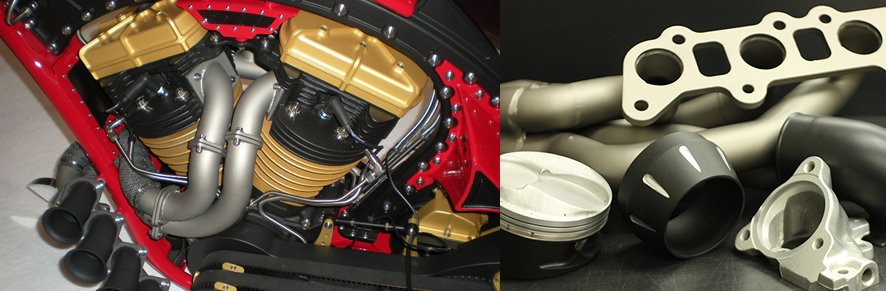

AmeriCoats offers silicone resin based powder coating with heat resistance up to 1200°F. This product line is suitable for a wide variety of applications including fireplaces, barbeques, heating appliances, automotive mufflers and headers, and other industrial applications. We also offer FDA compliance coating for direct and indirect food contact. They are available in a variety of colors and finishes.

This technology platform will meet key specifications up to AAMA 2605 and 625. These special resins now have a 10+ year track record, offering improved ultra violet stability versus Super Durable powders and improved hardness and stucco resistance versus Kynar resin based liquid and powder materials.

Bonded metallic powder coatings are produced by a proprietary process that attaches metallic pigments to powder particles resulting in a homogeneous incorporation of the metallic pigment throughout the finished product. The bonded metal-powder particles allow for consistent application properties, the development of uniform appearance of the cured paint film, and the reclaim-ability of overspray powder.

Specially formulated powders designed to restrict the growth of bacteria. These coatings are commonly used in kitchens, hospitals, schools and many other high use public areas.